The construction sector accounts for 6% of global GDP, $10 trillion in annual revenues, and is a driving force behind global economic growth and infrastructure advancements, while also forming the foundation for every other industry. Yet, despite the crucial nature of the sector, construction continues to be one of the least efficient in the world. Massive shortfalls with respect to construction workforce management are leading to counterproductive resource allocations and an overall inability to complete projects on-time and at budget.

However, the market is responding. Investment in construction technology has surged over recent years, and leading global contractors have placed an increased priority on technological adoption to drive productivity and profitability.

This article explores the components of construction workforce management, the root-cause of construction inefficiencies, the benefits to a workforce management program, as well as the best hardware and software solutions for world-class workforce management.

Or skip the read and start a conversation with a myComply rep about the leading construction workforce management solution for contractors worldwide.

Table of Contents

What is Construction Workforce Management?

The Problem: Outdated Tools and Systems for Workforce Management

The Benefits of Effective Construction Workforce Management

1. Cost Reduction

2. Data Collection

3. Enhanced Forecasting

The Lean Construction Model and Workforce Management’s Role

Best-in-Class Construction Workforce Management Software and Systems

1. Procore

2. myComply

Conclusion

What is Construction Workforce Management?

Construction workforce management can be defined as the combination of tools, technologies, and processes the project owners, General Contractors (GCs), and Construction Managers (CMs) use to enhance project efficiencies and ensure that they are deploying all labor and resources optimally.

- Tools. This category includes all the hardware-based solutions being used on-site to promote more efficient operations. Examples of tools that are often used for workforce management include: access control solutions, mobile communications technologies, as well as wearables and other worker monitoring tech.

- Technologies. This pertains to the complete software stack that is being leveraged on the project site, from preconstruction and building information modeling (BIM) technologies all the way through to financial management solutions. Check out Construction Technology: Adopt or Die to find out more.

- Processes. Tools and technologies are only as effective as the workflows that enable them. The final component of construction workforce management is the suite of training processes, communication practices, and performance metrics that guide day-to-day site operations for all workers and subtrades.

The Problem: Outdated Tools and Systems for Workforce Management

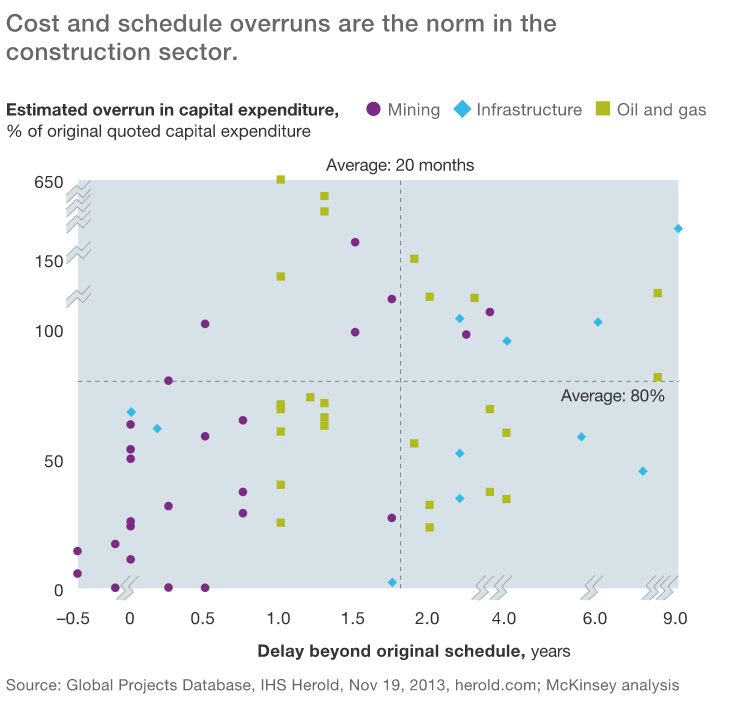

According to a study by McKinsey, mega construction projects are taking 20% longer to finish than scheduled, resulting in project completions that extend upwards of 80% over budget. As seen below, the infrastructure sector consistently exceeds both oil and gas, as well as mining with respect to capital overrun and project delays.

Source: McKinsey

Why is this?

Most believe that this is the result of insufficient investment in IT and technological innovations. In fact, the average R&D budget in construction continues to lag all other sectors at less than one percent of annual revenues. This can be compared to the automotive and aerospace sectors which clock in at 3.5% and 4.5%, respectively.

The result?

Massive operational inefficiencies, spanning all levels of construction projects. In fact, 35% of construction workers believe that greater than 14 hours a week are spent on non-productive activities, such as searching for job-required information, addressing/remedying mistakes, and completing rework-related activities.

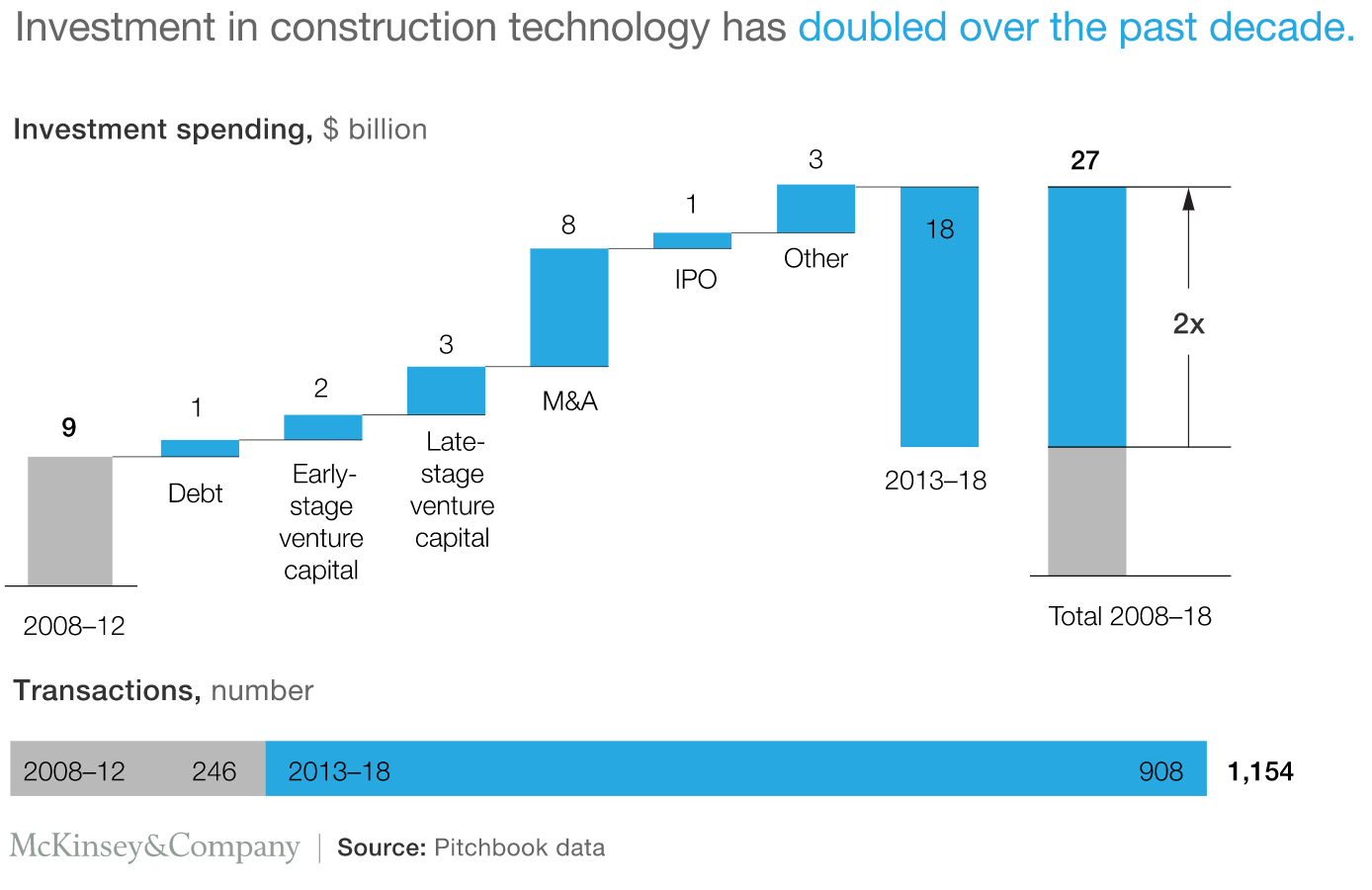

Fortunately, the tone is beginning to shift in the construction sector. A recent study by Software Connect determined that 81% of contractors plan to increase their investment in construction technology over the coming years. Additionally, a separate study by McKinsey on construction software investment found that investment in construction technology has doubled over the past decade, eclipsing $18 billion between 2013 and 2018.

Through increased investment and increased interest from construction companies, these new tools, technologies, and processes are enabling the leading contractors in the world to reduce the costs of outdated IT and deploy integrated construction workforce management strategies.

The Benefits of Effective Construction Workforce Management

When project owners, GCs, and CMs focus on construction workforce management, they win more bids, finish projects on time, meet budget, and drive stronger worker morale. Here is why.

1. Cost Reduction

Labor is one of the primary costs on all major construction projects, with recent reports suggesting that labor cost alone accounts for up to 40% of total project costs. That means that there are substantial savings to be had when construction workforce management becomes a focal point on your projects. In fact, in a recent project completed at the San Diego Community College District by Umstot Project and Facility Solutions, the implementation of lean construction practices led to savings of $13.6 million across 15 separate projects.

This was the result of fewer change orders, less rework, and more timely labor deployment. And this is all money that can be reinvested in future technological investments, better equipment for workers, or reinvested for future company growth.

Looking to lean-up your operations? Check out our in-depth article on the lean construction principles to learn more.

2. Data Collection

According to a study by the Zweig Group, only 0.5% of data collected by construction and engineering firms is being effectively utilized. Amongst that goldmine of data lies a wealth of labor insights that could be better utilized to analyze and improve scheduling, time and attendance, and more.

Note: Data collection is empowered by construction workforce management technologies, such as the ones that we will explore below.

3. Enhanced Forecasting

In construction, 90% of projects are not completed on time. This is a pervasive problem and leads to substantial cost overruns (as highlighted above). This failure to complete projects is dealt at the hand of consistent delays. In fact, a study by the Journal of Construction Engineering found that 28% of contractors reported very frequent delays, 61% reported frequent delays, and only 11% reported infrequent delays.

The natural extension of having more robust data, is an improved ability to forecast accurately. With workforce management technology, GCs and CMs can more accurately track the movement of workers and mitigate much of the risk of frequent/costly delays.

The Lean Construction Model and Workforce Management’s Role

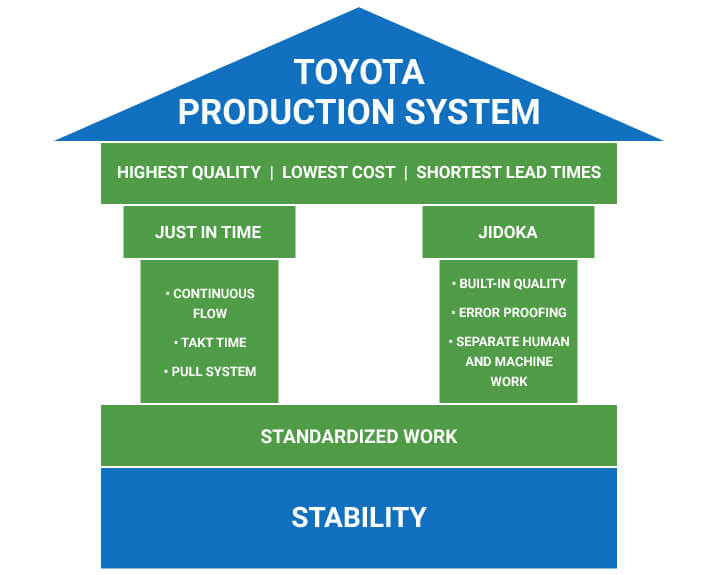

The lean construction model is an adaptation of the lean manufacturing model that was popularized by Toyota after the Second World War. The concept is simple: maximizing client value while minimizing waste.

Source: 5S Today

The lean construction model is comprised of five key principles:

- Identify value from the customer’s point of view. This applies to delighting every stakeholder, from owners, to suppliers, to every worker that engages with the project.

- Identify processes that deliver the value stream. This pertains to the elimination of project error, be that downtime, defect, overproduction, under-utilized talent, inventory inefficiencies, etc.

- Achieve flow of work processes. Reliable and predictable workflows is the name of the game.

- Use pull planning and scheduling. Pull planning is working in a downstream fashion to organize labor so that resources can be “pulled” in at precisely the right times in the project sequence. This is achieved through close subcontractor communication and GC coordination.

- Perfect the process through continuous improvement. The last step is to build a project culture that is open to continual improvements and adjustments.

Lean construction means a focus on eliminating waste in all areas of project operation and being that labor comprises nearly half of most project costs, workforce management is critical to the achievement of a lean construction project.

How to keep your labor lean:

- Supply your workers and subtrades with the equipment they need to communicate seamlessly so that you can address sources of waste quickly and ensure pull planning is maintained.

- There are two primary variables in construction: labor and resources. Scheduling resource delivery and labor deployment to align with each stage of project development is key to achieving reliable and predictable workflows.

- An emphasis on continuous improvement means constant changes to plan and workflow, which cannot be easily scaled without the use of project management technology. We will explore a couple of the best workforce management solutions in the section below.

Learn more: Lean Construction Principles: Engineering Project Success

Best-in-Class Construction Workforce Management Software and Systems

If you are looking to level-up your construction workforce management program, then these are the quintessential solutions that you should be considering.

1. Procore

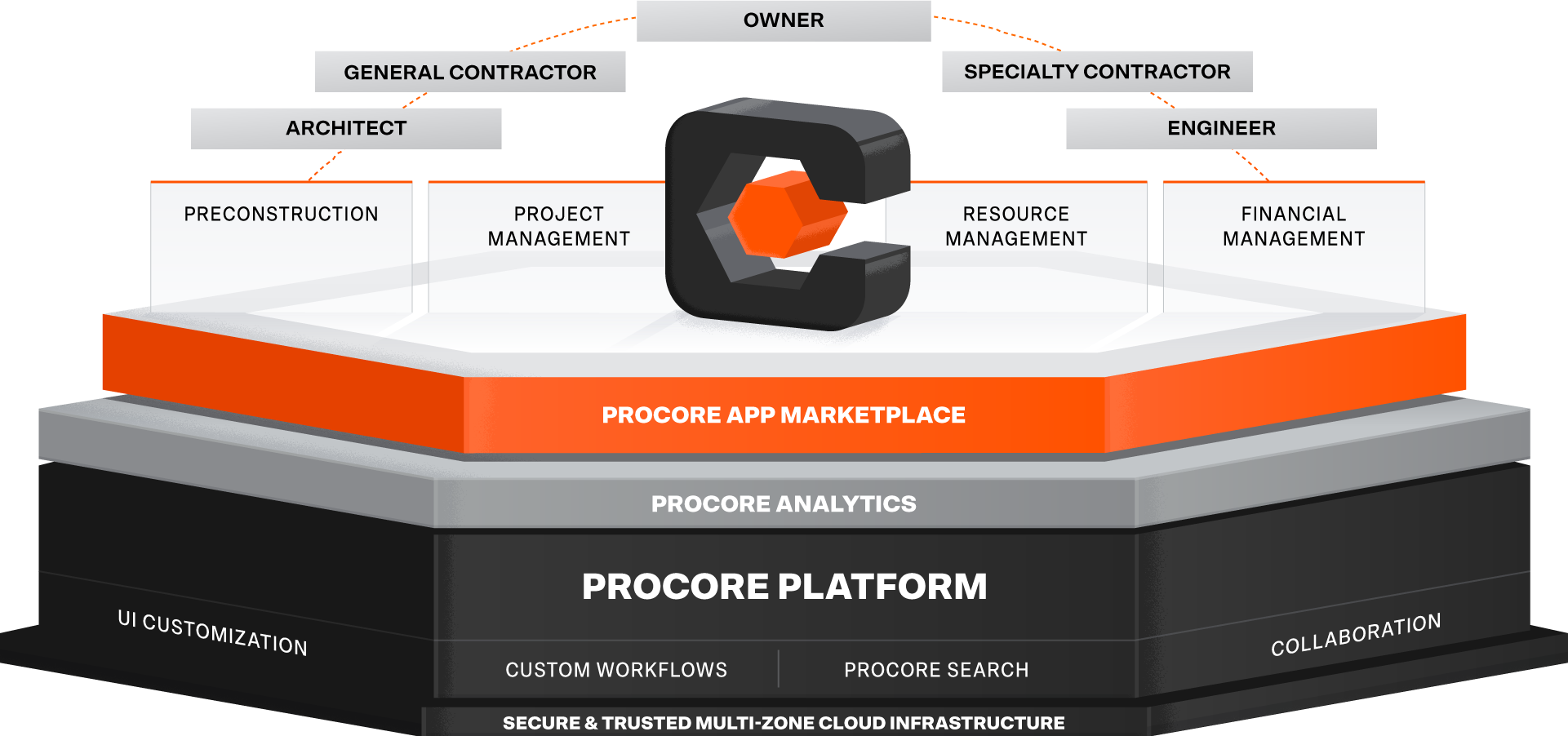

Procore is the leading project management solution in the construction space. With solutions for owners, GCs, and subcontractors, to assist at every stage of the project lifecycle, Procore is by far the most comprehensive project management solution for construction companies. If you want to improve your workforce management, then Procore should be your first stop.

Source: Procore

Why you need to consider using Procore:

- Drawing management and markup. Construction projects are always changing and adapting. With that, changes and modifications often happen to project plans. With Procore’s drawing technology, you can skip the sticky notes and markers. Instead, set user permissions and make changes to cloud-based drawings that can be digitally compared and overlayed, accessed on mobile devices, marked-up/commented on, and linked directly to RFIs, punch lists, submittals, (and more).

- Deep historical data. Every activity on every project, all the way from bidding, through to completion is tracked on a detailed digital record. That means that every document that is created, edited, approved, or deleted will be tracked in Procore. This can be instrumental in the case of lawsuit or to simply enhance bidding accuracy for future projects.

- Financial management. Procore’s financial management suite allows contractors to closely monitor the financial health of projects at every phase, so that you never miss budget. Dynamic data tracking makes it easy identify details and pivot when you need to. Plus, Procore can be integrated with leading accounting platforms like QuickBooks and Sage.

- The Procore App Marketplace. Home to 300+ integrations, this marketplace allows you to take a standard partnership and build it into one that meets your every unique need. You will find everything from enterprise management solutions such as Microsoft and Oracle, to point solutions such as Zoom and QuickBooks.

2. myComply

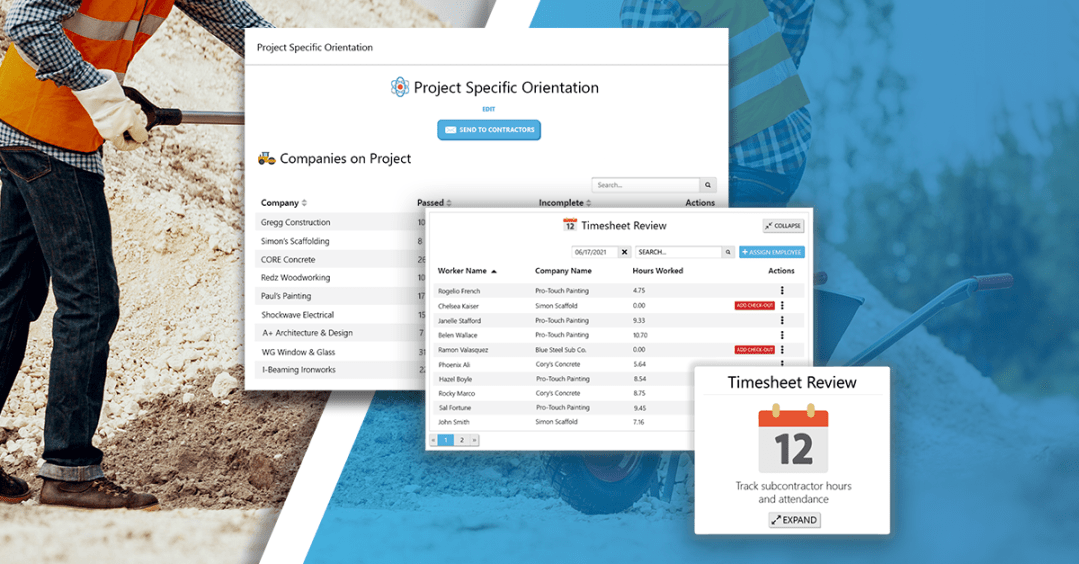

myComply is a hardware and software company that enables contractors to turn physical site assets into data drivers, safety enhancers, and staff regulators. If you are looking to eliminate the risk on non-compliance fines, take a preventative approach to ensuring site safety, and secure your project sites from the threat of damages or loss, then myComply is for you.

Why you need to consider using myComply:

- Construction site access control. This is a hardware/software combination that operates at the intersection of a qualified workforce and a secure jobsite. By integrating myComply Smart Bricks with door strikes or turnstiles on your projects, you can turn every entry/exit point into a time and attendance tracker as well as a qualification verifier. That means that no one gets on your project without having all their certifications up-to-date, and you never have to worry about inflated worker hours again.

- Projects Pro. This is the backbone of myComply’s software ecosystem. It allows GCs to manage every subtrade that they work with, every worker they employ, and every worker employed by each of their subtrades. Real-time analytics provide accurate project updates and on-demand reporting makes it easy to show progress data.

- Online orientations. Need (or want) to deliver orientations digitally? This new solution enables GCs to create custom orientations programs that can be delivered to workers online, in-person, or a combination of the two.

- Procore and Autodesk integrations. If you are already using one of the leading construction technology solutions, then seamlessly integrate and share data between the platforms. For example, the Procore integration allows you to import projects and profiles from Procore into myComply while shipping time and attendance data back to Procore to backfill documentation and complete Procore’s Daily Log.

Conclusion

Construction workforce management is not a new concept. However, new tools, technologies, and processes are making it easier than ever before to enhance operational efficiencies and improve your bottom line.

By adopting leading tech solutions like Procore and myComply and implementing lean construction work methodologies, you stand to slash production costs, improve workforce visibility, and enhance human resource management capabilities; all of which will lead to greater performance, greater forecasting accuracy and a stronger bottom line.

Start your journey to a more profitable tomorrow by procuring your own myComply Starter Kit today!